The FDA plays a crucial role in ensuring that all pharmaceutical products, including active pharmaceutical ingredients (APIs), meet the highest standards of quality and safety. To achieve this, the FDA has developed a robust framework for inspecting and regulating API manufacturing, grounded in the principles of Good Manufacturing Practices (cGMP). Central to this framework is the “Six Systems Approach,” a comprehensive method that ensures every aspect of the manufacturing process is meticulously monitored and controlled.

FDA compliance programs are designed to ensure that pharmaceutical activities adhere to the American Federal Food, Drug, and Cosmetic Act, along with other pertinent regulations. These programs, accessible to the public under the Freedom of Information Act, provide detailed instructions to inspectors on how to evaluate the compliance of pharmaceutical manufacturing activities.

According to Section 501(a)(2)(B) of the Act, an API can be considered adulterated if it contains harmful impurities or fails to meet the expected standards of content, quality, and purity. Such a failure to comply with cGMP is a direct violation of the Act. Therefore, as API manufacturers we must operate in a «state of control», adhering to the conditions and practices that guarantee compliance with these legal requirements.

To effectively oversee API manufacturing, the FDA employs a “Six Systems Approach,” which breaks down the inspection process into six key areas. This method allows for a thorough evaluation of each system involved in the production process, ensuring that all aspects of manufacturing are in compliance with regulatory standards. The six systems are as follows:

Quality System: The quality system is the cornerstone of the FDA’s approach, overseeing the other five systems. It involves two primary areas: document control and problem management. Document control ensures that all procedures are properly documented and used by qualified personnel, while problem management focuses on addressing and resolving quality issues.

Materials System: This system governs the control and management of all materials used in API manufacturing, including raw materials and packaging. It encompasses the supply chain, quality control, sampling, labelling, and storage. The materials system also includes the validation of electronic systems related to materials management.

Buildings and Equipment System: Ensuring that manufacturing environments and equipment are appropriate for producing high-quality APIs is the focus of this system. It assesses the suitability of facilities, equipment maintenance, and staff training to ensure compliance with established procedures.

Production System: The production system covers the actual manufacturing processes, emphasizing the importance of written and approved procedures. This system also involves the monitoring and control of critical points within the production process, as well as the validation of these processes to maintain product quality.

Packaging and Labelling System: This system oversees the packaging and labeling of APIs, ensuring that all operations are conducted according to strict procedures. It includes the management of change, label printing and storage, and the validation of related processes and electronic systems.

Laboratory Control System: Laboratory control is essential for verifying the quality of APIs. This system includes the management of laboratory facilities, personnel, and methods used for testing and validation. It also involves the control of data and quality indicators to ensure the accuracy and reliability of laboratory results.

The FDA’s inspection approach is aligned with the International Council for Harmonisation (ICH) Q7 guidelines, which provide a global standard for API production. These guidelines cover various aspects of the manufacturing process, including quality management, personnel, documentation, and laboratory controls. By adhering to ICH Q7, API manufacturers ensure that their products meet international standards of quality and safety.

The FDA’s Six Systems Approach is a comprehensive method designed to safeguard the quality and safety of APIs. By carefully evaluating each system involved in the production process, the FDA ensures that all APIs meet the stringent requirements set forth by law. This meticulous approach not only protects public health but also maintains the integrity of the pharmaceutical industry, ensuring that all products are manufactured to the highest possible standards.

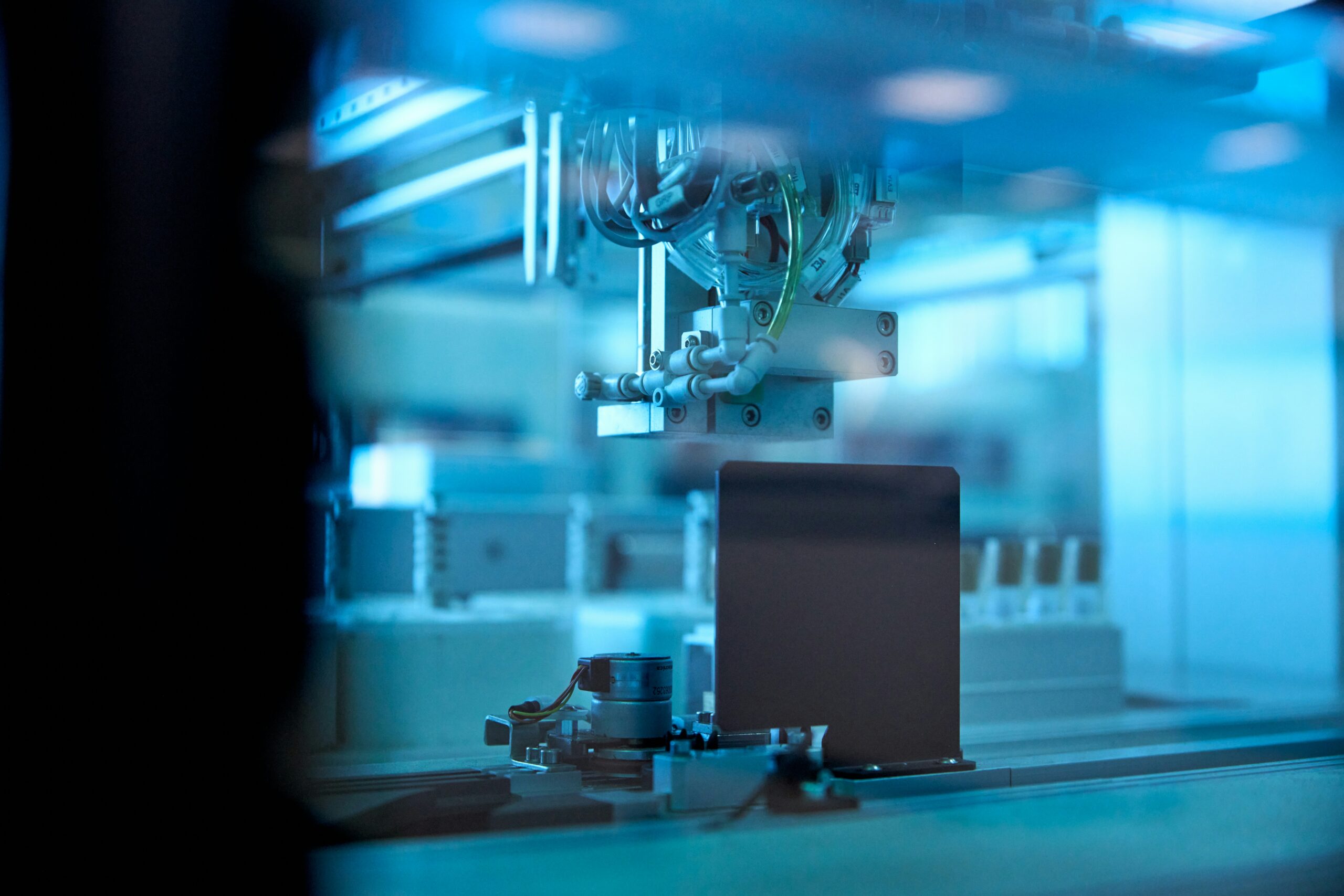

At Seratec, quality is not just a goal—it’s the foundation of everything we do and embedded throughout the entire product life cycle.

The Pharmaceutical Quality System (PQS) is a management framework ensuring consistent production of high-quality products.

Seratec specializes in areas ranging from developing active molecules to offering turnkey solutions for APIs.